Wednesday 5 July 2017

Thursday 18 May 2017

Metal Powder Coating Services, Powder Coating on Products

|

| Powder Coating |

Avitron has State-of-Art Painting Facility

- PLC Controlled Pre Treatment with transporter

- Conveyorised Powder Coating

- ITW GemaReciprocator & spray Guns- to achieve uniform spraying of paint

- Testing equipment : Cross hatch, Bend test to check the adhesion.

Powder Coating processes of Avitron are environment-friendly and are technologically advanced way of finishing off an end product. What is really good about our Powder coating processes is the unused powder can be recycled entirely and be used all over again. Therefore we help in promoting a Green environment.

Our large facility in Gurgaon can easily accommodate large sized parts within our powder coating process. Also, our skilled painters have experience of providing excellent finishes to your product, either by hand or a wet spray alternative. We have stock of standard colors finishes with different variations of Gloss, Satin, Texture, Matt, and Polyester.

Product Design Services, Industrial Autocad Designers

What is really good about Avitron is that we have vast experience in designing various components that are required for manufacturing and final assembly. Due to this, we are able to lessen lead times, minimize costs, improve usability and visual style, and guarantee quality.

Software used:

Our professional and experienced, in-house team will work tirelessly alongside custom designers for adding value through various stages of design, development, and at point of use.

Our customers have always appreciated our ability to create impeccable engineering drawings and CAD designs from mere concepts and sketches using various manufacturing techniques.

Also, we are able to create 3D images from available CAD designs to enable our customers have a look at the completed sheet metal fabrication products.

Our aim will always be to:

- Solid Works 3D

- Solid Edge

- Solid Works EPDM

- Solid Works Inspection

- SAP

Our professional and experienced, in-house team will work tirelessly alongside custom designers for adding value through various stages of design, development, and at point of use.

Our customers have always appreciated our ability to create impeccable engineering drawings and CAD designs from mere concepts and sketches using various manufacturing techniques.

Also, we are able to create 3D images from available CAD designs to enable our customers have a look at the completed sheet metal fabrication products.

Our aim will always be to:

- Reduce lead times

- Create detailed engineering drawings and CAD designs using the best-in-class Design for Manufacture technique.

- Reduce sheet metal/product fabrication costs by providing low cost design options in-house.

- Improved design to enable cost reduction, improved visibility and usability.

Saturday 15 April 2017

Customized Fabrication Works for Telecom Industry

|

CUSTOMIZED FABRICATION WORKS |

Avitron has an enviable position in the market. Therefore, in order to maintain our high standard and to continue remaining as one of market leaders, we make sure to provide exceptional quality and customized fabrication works for all industries like Electricals & Electronics.

All our customized fabrication works that are available for a number of industry verticals are carried out by our team of professionals that have exceptional talent and experience in their respective domains. To ensure we are able to meet your expectations, we employ only the best of technologies and advanced machines. Furthermore, we make sure to provide the customized fabrication works in accordance with the standards set in the industry.

It is our constant endeavor to provide fabrication works that are incredible in quality and will enhance the life of your structures.

Customized Office Furniture Manufacturers, Metal Street Furniture

|

STREET FURNITURE |

At Avitron, we fully understand your design considerations that are associated with public infrastructure - utility and esthetics, durability, and portability.

A number of public infrastructure applications have been featuring fabricated decorative sheet metal and thereby contributing to eye-catching Signage, Barrier screening, and amenity within parks, roads, playgrounds, gardens, and nature reserves.

We are increasingly seeing metal works incorporated within open space environment and urban streetscape, albeit in various forms - like Picnic tables, Park benches, Trash bins, enclosures, Drinking fountains, Fences, etc.

Understanding this need, Avitron is willing to work closely with landscape architects, private developers, and government institutions to give valuable design suggestions and help develop custom sheet metal street furniture. We will employ the best of materials, manufacturing processes, and laser cutting effects to meet your objectives.

products display racks, gondola racks and retail stores display

Major retail outlets, Global brand Shops, dealers, distributors, are always in need of custom manufacturing for POP (point-of-purchase) Displays. Besides this, they are always on the lookout for customized solutions that will provide durability, outstanding craftsmanship, from an expert and experienced provider who is capable of handling large-scale rollouts.

Thats where Avitron can bring in the difference you have been looking for. With all of retail display processes carried out in-house, you can always expect short lead-times and quality to be at-par with the industry standard.

Some Retail Display Options for you:

Why choose us?

Thats where Avitron can bring in the difference you have been looking for. With all of retail display processes carried out in-house, you can always expect short lead-times and quality to be at-par with the industry standard.

Some Retail Display Options for you:

- Gandolas

- Countertops

- Cash wraps

- Fixtures

- Floor standings

- Sign holders, and much more

- Our Retail Displays are creative

- Availability of custom designs

- High-quality sheet metal fabrication

- Optimum quality

- Ability to meet aggressive deadlines

- Durable

- Affordable

Vending Machine Cabinets, Sheet Metal Inverter Cabinets

|

| Cabinets |

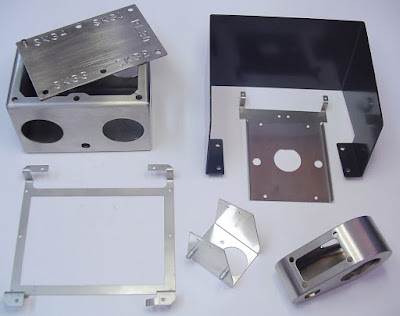

Our top-of-the-line sheet metal fabrication processes are capable of designing and developing cabinets of various kinds. From Storage cabinets to Electrical(UPS, Transformer, Servo) cabinets, Vending machine cabinets, Kitchen cabinets, Medical Instruments to Electronics Instrument cabinets, Telecom Racks, Machine enclosures, we can have all of them developed for you, according to your requirements, specs and budget.

Our custom-made cabinets are truly one-of-a-kind and are extremely suitable for a wide-range of applications including, computer storage, telecommunications, industrial equipment, lighting, retail, hospitality, and much more.

Raw materials:

Mild Steel, Stainless Steel, Galvanized Steel (GI/GP), Aluminum, PEM fastners

Lead times.

Dependent on the volumes, generally 2-3 weeks.

Can cater to some urgent requirements - prototypes in 1-2 days.

Processes involved:

CNC Punching, CNC Laser Cut, Bending, Robotic Welding, Powder Coating, Hot Dip Galvanizing, Pad Printing.

Tuesday 31 January 2017

Vending Machine Cabinets, Kitchen Cabinets, Medical Instruments to Electronics Instrument Cabinets, Telecom Racks, Machine Enclosures

Our top-of-the-line sheet metal fabrication processes are capable of designing and developing cabinets of various kinds. From Storage cabinets to Electrical(UPS, Transformer, Servo) cabinets, Vending machine cabinets, Kitchen cabinets, Medical Instruments to Electronics Instrument cabinets, Telecom Racks, Machine enclosures, we can have all of them developed for you, according to your requirements, specs and budget.

Our custom-made cabinets are truly one-of-a-kind and are extremely suitable for a wide-range of applications including, computer storage, telecommunications, industrial equipment, lighting, retail, hospitality, and much more.

Raw materials:

Mild Steel, Stainless Steel, Galvanized Steel (GI/GP), Aluminum, PEM fastners

Lead times

Dependent on the volumes, generally 2-3 weeks.

Can cater to some urgent requirements - prototypes in 1-2 days

Processes involved:

CNC Punching, CNC Laser Cut, Bending, Robotic Welding, Powder Coating, Hot Dip Galvanizing, Pad Printing

Subscribe to:

Posts (Atom)